Unique handcrafted processes

At Pulvis Art Urns, every ceramic piece is created at an unhurried pace, with the same care, precision, and devotion once shown by the master ceramists of old Bulgaria. Our work remains entirely handcrafted in Bulgaria, at our sole studio and factory near Sofia—a place where tradition and innovation meet in quiet harmony.

Guided by a team of passionately dedicated designers and artists, Pulvis produces contemporary memorial urns that are deeply inspired by art, sculpture, and modern design. From the shaping of raw clay to the final glaze, every step—glazing, modeling, carving, etching, and hand-painting—is performed with meticulous attention to detail.

These skilled hands do more than create urns—they preserve ancient ceramic traditions, breathing life into clay and transforming it into timeless memorial art.

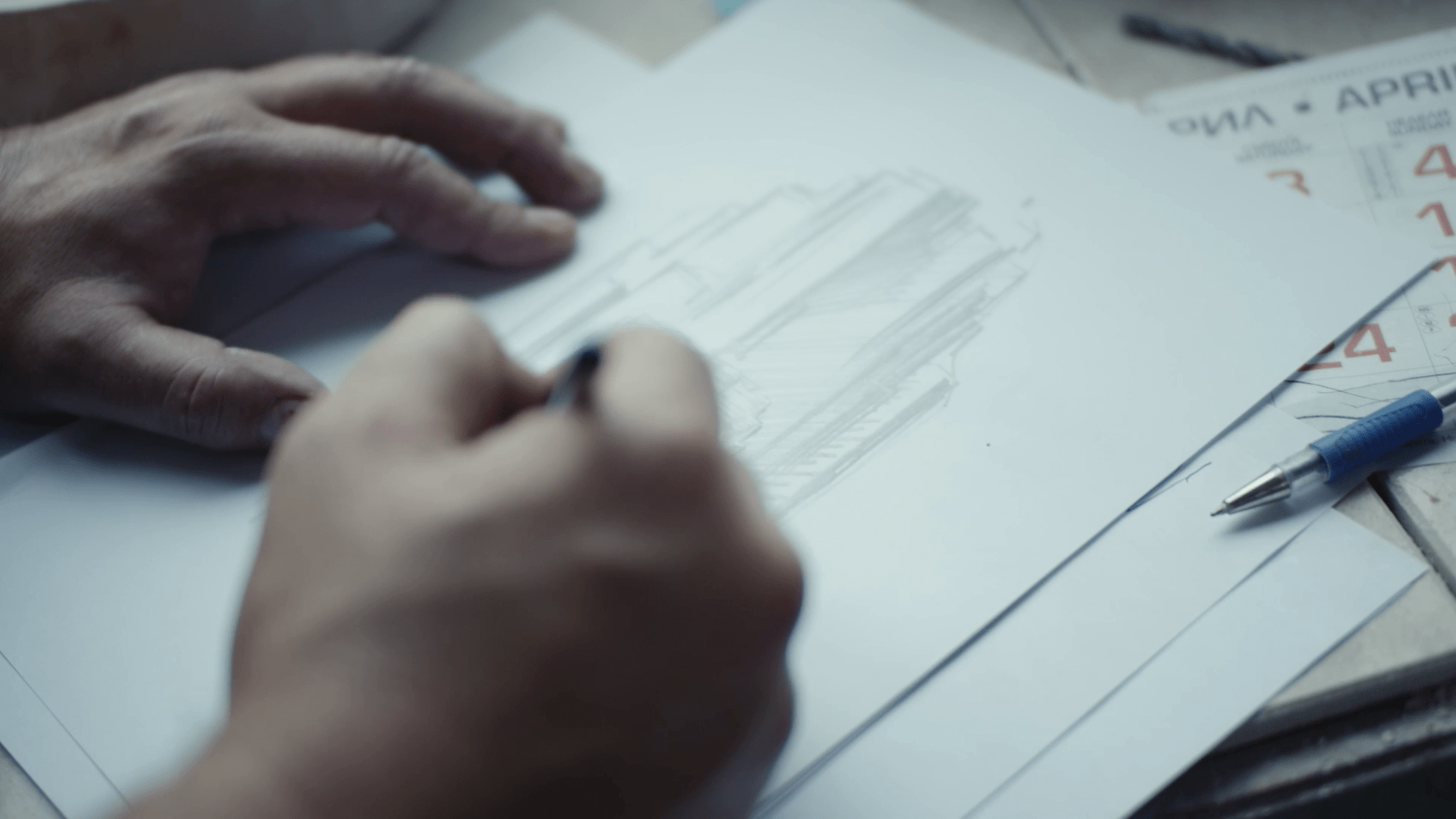

The Birth of a Pulvis Art Urn

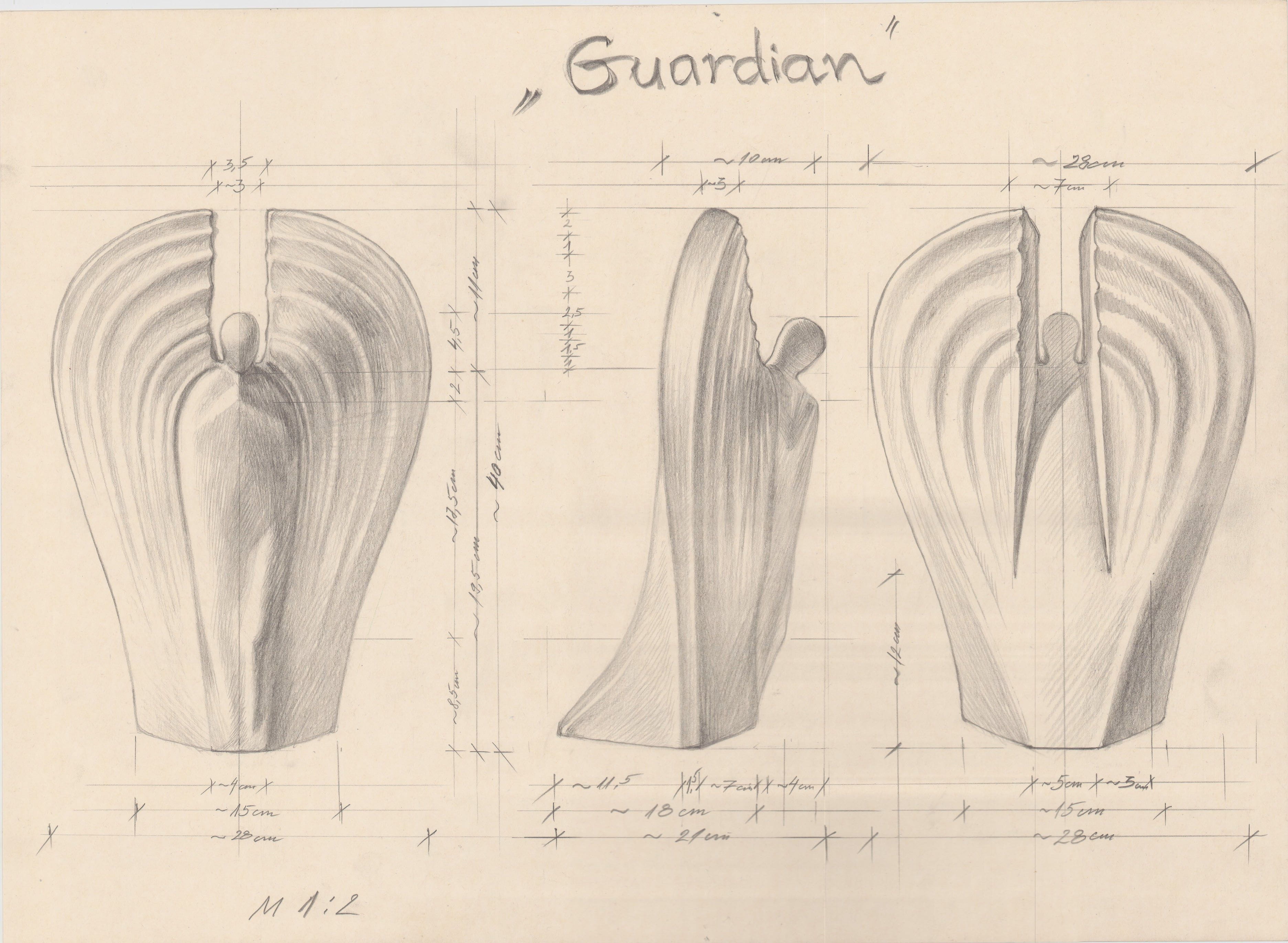

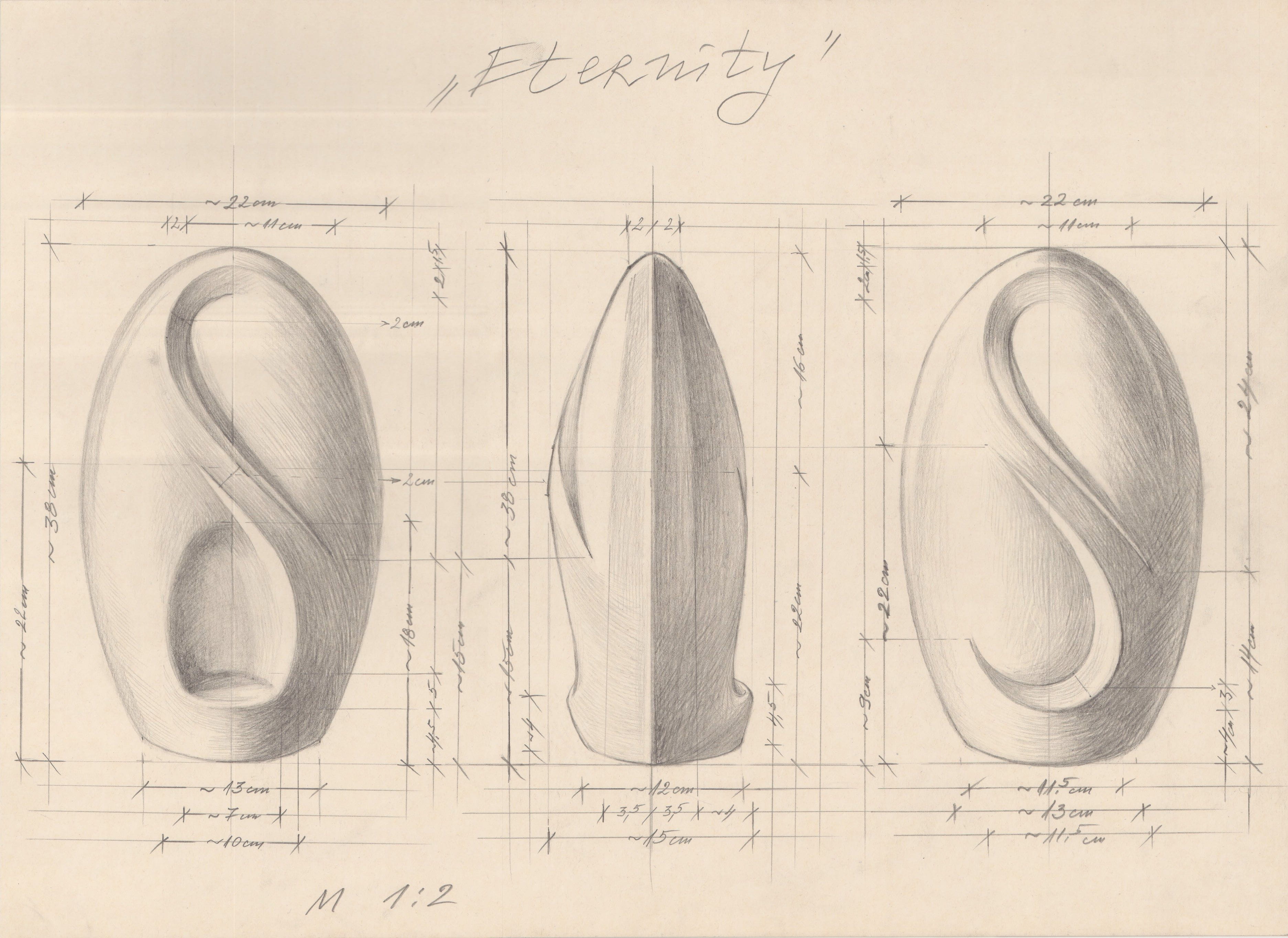

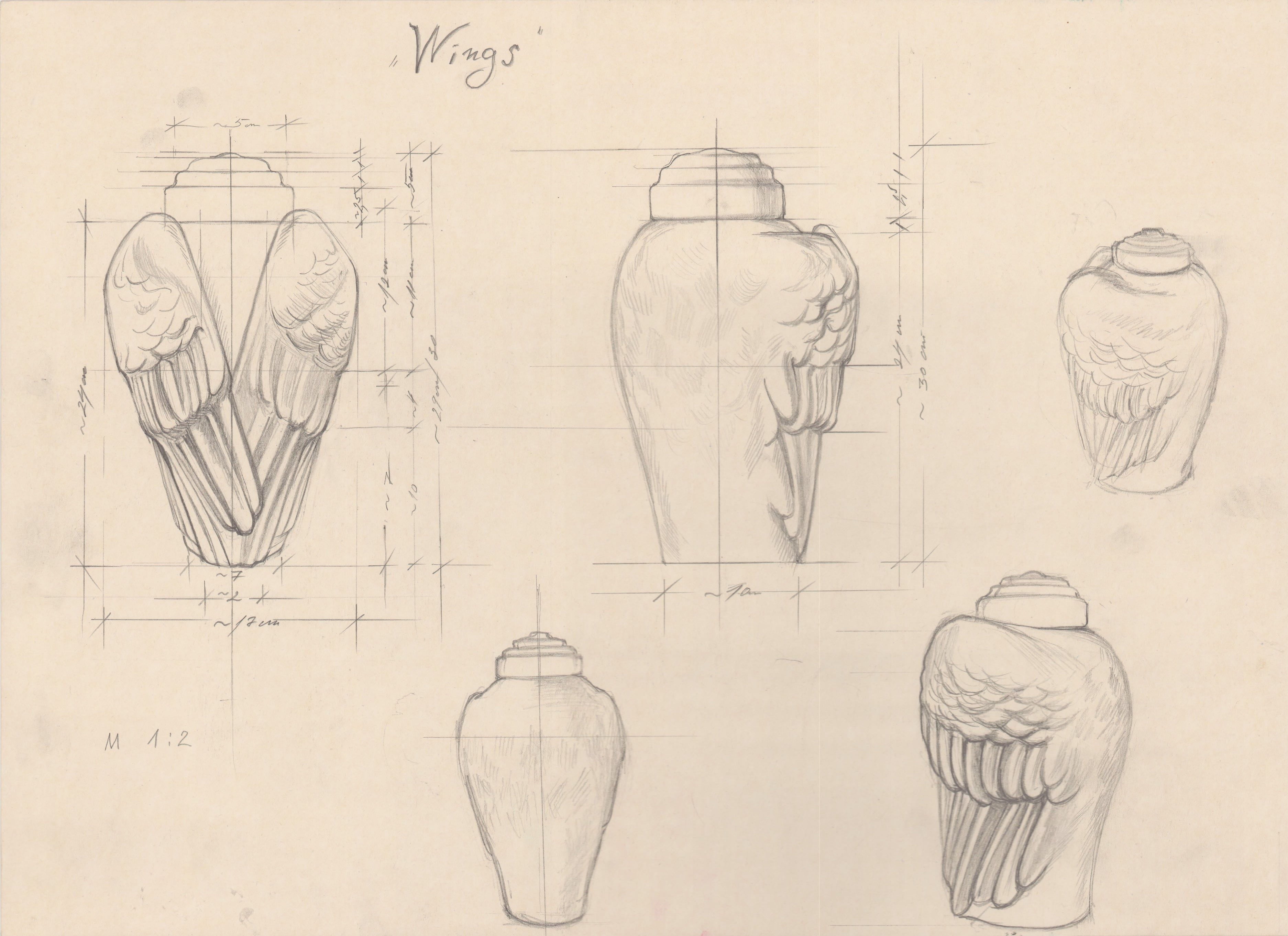

Every Pulvis ceramic urn begins with a spark of inspiration—an idea sketched by hand and shaped by heart. Using traditional tools and time-honored techniques, our sculptors model the initial form in clay or wax, often drawing from live studies, symbolic references, and extensive artistic research.

Once the concept takes shape, the piece enters a deeply technical and creative phase. Our expert team must carefully visualize how each complex form will be divided into fragments for casting and assembly. Some of our most intricate urns are composed of hundreds of meticulously crafted parts, later fused into a seamless, sculptural whole.

It is a process where artistry, precision, and passion come together—transforming raw material into meaningful memorial art.

Shape & form

Once the sketch has been modelled, the exciting artistic development of the original model begins. The technical team must visualize and define the fragments in which each piece will be broken down in order to reproduce it later. There are ceramic urn models so complex that they need to be divided into more than 20 fragments.

These fragments will form the basis to create the matrix molds, that are used to obtain the definitive molds. This carefully executed artistic process, from the birth of the idea until the ceramic urn is ready to be reproduced in ceramics, can take up to a year for the most complex creations in the exclusive cremation urns collection.

Perfection to the smallest detail

Century-old gestures and know-how, passed down from generation to generation, are what it takes to achieve perfection in every step of our process. At the heart of each urn we create lies the mastery of traditional techniques such as pottery wheel throwing, sculpting, and fine hand-carving.

Our ceramists, with over 30 years of experience, embody this deep heritage—bringing not only technical skill but also soul and sensitivity to every piece. Their hands have shaped thousands of forms, but each one remains unique, a testament to the timeless craft that defines our work.

The magic of ceramics

To bring each piece to life, our artisans begin by pouring liquid ceramic into meticulously crafted molds, allowing it to slowly take shape within. Once set, the delicate components are carefully removed—each part like a fragment of a magical puzzle—and skillfully reassembled by hand.

Over time, these molds naturally wear down, and must be recreated from their original matrix, preserving the integrity and precision of the form. This process, though demanding, is essential to maintaining the artistry and authenticity that define our creations.

Masters of color

Another key moment in this creative journey is the glazing process. With a palette of over 80 unique colors—and more being added regularly—Pulvis Art Urns continues to innovate, developing exclusive tonalities tailored to specific designs. This evolving spectrum reflects our commitment to artistic expression and individuality in every piece.

Thanks to decades of expertise, Pulvis offers a wide array of decorative techniques—liquid pigments, lusters, and enamels—alongside a rich variety of textures and finishes, from high-gloss to matte and satin. Each urn is a canvas, and our master painters apply color with a steady, practiced hand, delicately tracing even the tiniest details to bring every design to life with unmatched precision and care.

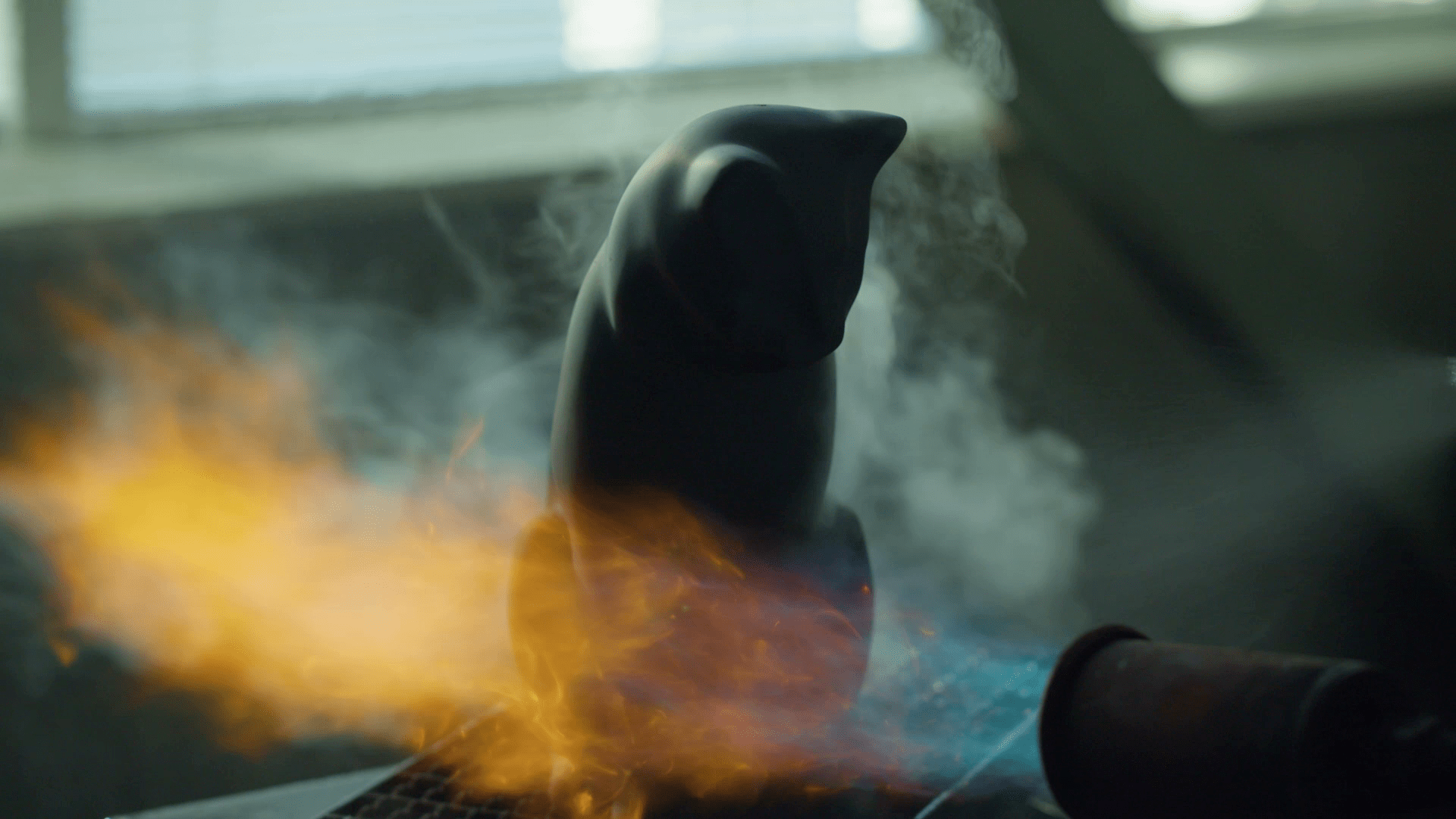

The test of fire

Firing in the kiln is a pivotal moment—one that every Pulvis piece undergoes not once, but twice. As our artists often say, ceramics is alive, and it is in the intense heat of the kiln that each handmade creation proves its strength and beauty.

Exposed to temperatures reaching up to 1,200ºC (2,200ºF) over the course of an entire night, our ceramics undergo a dramatic transformation. It is here, in the heart of the flame, that the true Pulvis colors are revealed—deep, rich, and unmistakably unique. This final trial of fire is where craftsmanship meets nature, and art becomes eternal.

Quest for excellence

The pieces are selected not only according to technical criteria (absence of defects) but also according to aesthetic considerations, paying full respect to the creative team’s intentions.

The search for perfection also extends to quality control, where the finished product undergoes various tests that certify that it fulfils the high standards demanded by the brand.

Since 2020 Pulvis Art Urns is certified according to ISO - 9001, ISO - 1400 and ISO - 45001 standards.

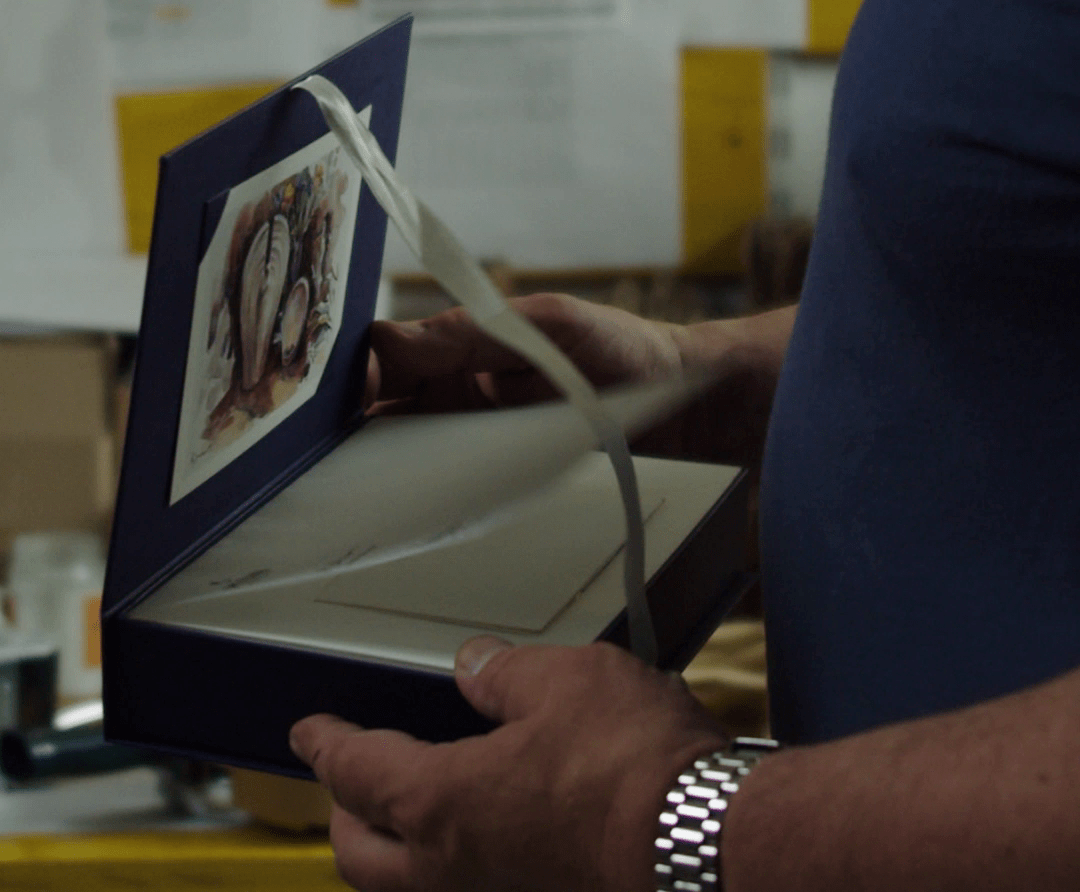

Shapes of spirit

From artist's inspiration, through glazing and firing, all the way to the packaging, Pulvis Art Urns team is dedicated in creating not just handmade urns, but Shapes of spirit.

Excellence is also applied in the packaging, customized to the individual features of each piece in order to ensure that it reaches its final destination safely and in perfect conditions.